Furnace Download Brochure

Installation and commissioning services for various kinds of Electrical Furnaces

With our detailed planning and full on site installation service provided by our experts, you will sure that your equipment will be installed properly and as per the scheduled promised regardless of they are new – retrofit-or upgrade projects.

Commissioning is followed by on site training of your personnel. Our services also includes performance testings and acceptable criteria as applicable.

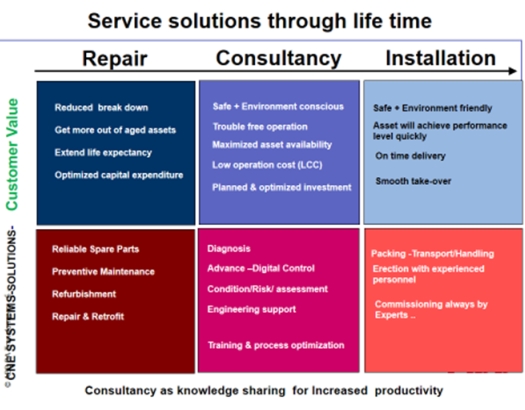

Customer Value

- Genuine Single source support

- Professional site management

- Long equipment service life

Maintenance and Inspection

To ensure reliability and long service life of your CNE Systems equipment periodical maintenance and inspection services are necessary. We have competent and professional experts to provide you with services as per prefixed maintenance contract

As your long term service partner,it will be our endeavour to ensure maximum availability of your equipment and thus reliability of production.

Our customer Value

- Preventive maintenance

- Higher uptime of equipment

- Long service life

Repair

Quick and proper repair is carried out at our/our sub suppliers factory as well as at site as per requirement to put back the equipment in operation in shortest possible time.

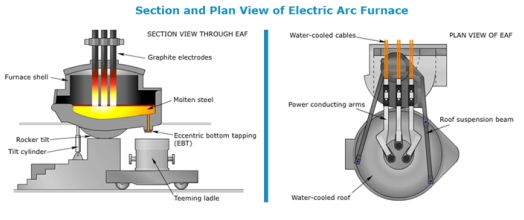

For steel plant sector,we offer our repair service for following items.

- Water cooled panels for Shell and Roof

- Electrode clamps and water cooled current carrying cables

- Transformer-Reactor ,HT breaker

- Hydraulic Power pack

- For foundry technology sector ,we offer repair services for following items

- Coils and coil assembly

- Furnace Structurals

- DC choke and its coils

- Channel furnace Inductors

Retrofit - Modernization

CNE Systems also retrofit and modernize old equipment to meet the latest technological and production requirements of the plants.Moreover ,we also upgrade your existing systems /equipment with State of Art technology like Digital regulation and control systems.

For example for steel and foundry sector

- Replacement of Electrical control cabinet

- For Electric Arc –LF furnaces –Upgrade Electrode regulation with Digital type

- Conventional Electrode holding Arms to Current conducting Arms

- Increase power level of Electrical Furnaces

- Conversion from Main frequency to Medium frequency

Spare parts and services

CNE System ensure timely and genune spares parts supply for your equipment.

- The parts of stock can be delivered within 24 hours

- Supply of outsourced items are ensured for delivery with our long terms association with our sub vendors.

- All parts manufactured by us or outsourced go for quality inspection to meet its quality standards.

Training / Process optimization

Quite extensive training to your personnel improves the operational efficiency of the plant. The training reduces operators mistake and enables them to solve minor problem themselves.

Training is taylor made to suit plant specific need. The training typically includes

- Operation and maintenance

- Parameter setting –adjustment and fault diagnosis

- Handling of water cooling and hydraulic system/components

- Theory and practical of Static frequency convertors

- Melting and refining processes and optimization